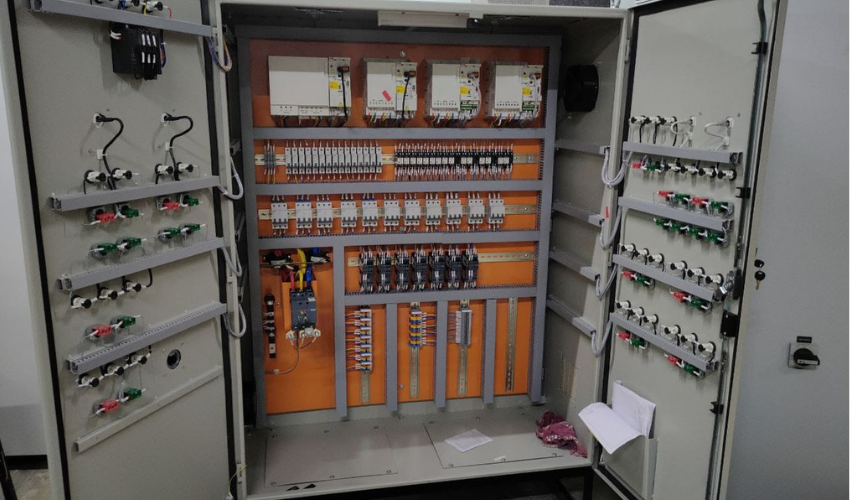

VFD Operated Panel

A VFD Operated Panel is an electrical control panel designed to

regulate the speed, torque, and direction of electric motors using

Variable Frequency Drives (VFDs). These panels optimize energy

consumption, improve motor performance, and provide smooth

motor operation across various industrial applications.

1. Purpose of a VFD Panel

- Energy Efficiency – Reduces power consumption by adjusting motor speed

- Smooth Motor Control – Provides soft start and acceleration to prevent sudden shocks

- Process Automation – Allows speed variation based on demand.

- Extended Motor Life – Minimizes mechanical stress and heat generation.

- Remote Monitoring & Control – Integrates with SCADA/HMI systems.

2. Components of a VFD Operated Panel

A. Electrical Protection Devices

- MCCB (Molded Case Circuit Breaker) – Protects against short circuits & overloads.

- MCB (Miniature Circuit Breaker) – Used for control circuit protection.

- Overload Relays – Prevents excessive current draw from motors.

- Surge Protection Devices (SPD) – Shields against voltage spikes.

B. Motor Control & Switching Devices

- Variable Frequency Drive (VFD) – Adjusts motor speed & torque

- Bypass Contactor – Ensures motor operation in case of VFD failure

- Soft Start Feature – Reduces inrush current during motor startup

- Brake Resistors – Helps in controlled motor stopping (for high-inertia loads)

C. Monitoring & Communication

- HMI (Human Machine Interface) – Touchscreen display for control & monitoring

- Multifunction Energy Meters – Monitors voltage, current, frequency, and power factor

- Communication Protocols – Modbus, Profibus, Ethernet/IP, BACnet for automation

3. Types of VFD Panels

A. Based on Application

- Single Motor VFD Panel – Controls one motor at variable speed

- Multi-Motor VFD Panel – Operates multiple motors using a single VFD with intelligent

switching

- Pump Control VFD Panel – Optimized for water pumping applications (constant

pressure).

- Fan & Blower VFD Panel – Used in HVAC, ventilation, and industrial exhaust systems.

B. Based on Power Rating

- Low Voltage VFD Panel – 0.5 HP to 500 HP (415V, 230V)

- Medium Voltage VFD Panel – 500 HP and above (3.3kV, 6.6kV, 11kV)

4. Technical Specifications

- Operating Voltage: 230V / 415V / 690V AC

- Frequency Range: 0 – 50/60 Hz (Adjustable)

- Motor Capacity: 0.5 HP to 1000 HP+

- Enclosure Protection: IP42, IP54, IP55, IP65 (Dust & Water Resistant)

- Cooling System: Forced Air Cooling / Heat Exchanger

5. Applications of VFD Panels

- Industrial Automation – Variable-speed conveyors, crushers, extruders

- Water & Wastewater Treatment – Pumping stations, borewells

- HVAC Systems – Chillers, fans, blowers

- Power Plants – Boiler feed pumps, turbines

- Oil & Gas – Compressors, drilling rigs

6. Benefits of VFD Panels

- Reduces Energy Bills by 30-50% through motor speed control.

- Eliminates Sudden Mechanical Stress on motors & connected equipment.

- Increases System Reliability with advanced monitoring & fault detection.

- Improves Process Efficiency by dynamically adjusting speed & torque