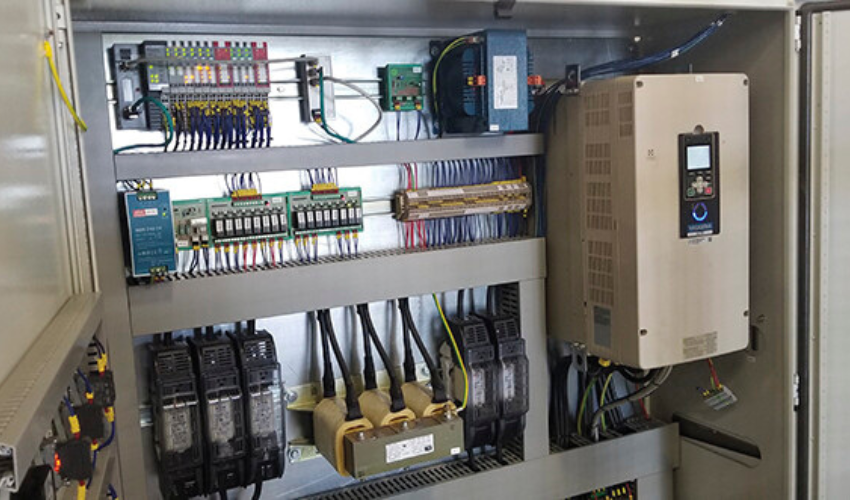

Temperature Controller VFD

A Temperature Controller with VFD is a system that regulates motor

speed (fans, pumps, compressors, etc.) based on real-time

temperature variations. This setup is commonly used in HVAC,

furnaces, chillers, cooling towers, and industrial processes to

enhance energy efficiency and precise temperature control.

How Temperature Controller Works with VFD

1.Temperature Sensor (RTD, Thermocouple, or

Infrared Sensor)

- Measures the process temperature.

2.Temperature Controller (PID Controller, PLC, or HMI)

- Compares the measured temperature with the setpoint

(desired temperature).

- Sends a control signal based on the difference.

3.Variable Frequency Drive (VFD)

- Adjusts motor speed based on the temperature

controller’s signal.

- Increases speed when more cooling/heating is needed

and reduces speed when stable.

4.Motor (Fan, Pump, Blower, or Compressor)

- Runs at variable speeds to maintain temperature control

efficiently.

Benefits of Temperature Controller with VFD

- Energy Savings – Reduces power consumption by operating

motors at optimal speed.

- Precise Temperature Regulation – Eliminates sudden fluctuations

and overshooting.

- Extended Motor Life – Avoids frequent start/stop cycles.

- Reduced Maintenance Costs – Lowers mechanical stress on

equipment.

- Automation & Remote Monitoring – Can integrate with PLC,

SCADA, or IoT.

Applications of Temperature Controller with VFD

- HVAC Systems – Adjusts blower or fan speed for efficient airflow.

- Industrial Furnaces & Ovens – Controls exhaust fans to maintain

uniform heating.

- Chiller & Cooling Towers – Varies pump/fan speeds for optimal

cooling efficiency.

- Greenhouses & Climate Control – Regulates ventilation fans

based on temperature.

- Oil & Gas Processing – Manages pumps and compressors for

heat-sensitive operations